Do You need an Industrial PC or Commercial PC?

By their nature, PCs (personal computers) are able to help with problems in nearly any domain. As automation technology becomes more sophisticated, there is growing incentive to use PCs in manufacturing, utility management, and other industrial settings. However, the physical environments surrounding these applications are unsuitable for everyday computers. Dust, water, extreme temperatures, and other factors can all damage equipment and affect performance.

IPCs (industrial personal computers) are specifically built for use in these inhospitable conditions. Equally important, IPCs back these claims up with the ratings and certifications that are required in many real-world scenarios. Behind the industrial-grade construction, IPCs are essentially traditional computers with all of the usual parts, and can accomplish all the same tasks that a regular computer can. Most IPCs also offer additional features which help when working with other industrial equipment.

Environmental Ratings

An IPC will typically operate in harsh conditions, and will be exposed to circumstances not common in an office setting. Although a normal computer may seem sufficient, there is always a possibility of sudden malfunction or degradation in performance. More importantly, there is no legal assurance that the product will work as intended. This makes commercial PCs undesirable for most government contracts and safety-critical operations.

To accommodate these needs, the IEC and other organizations provide ratings and certifications for industrial electronics. One important case is the IP rating, which specifies a level of tolerance to dust and water. For example, “IP65” indicates a dust tolerance of 6 (full protection) and a water tolerance of 5 (being sprayed by a nozzle jet will have no harmful effect). There are quite a few other ratings, and the exact requirements can vary from industry to industry.

Some common factors to consider include:

- Temperature: Processors can easily overheat, while mechanical components and LCDs may stop working below freezing

- Sunlight: Direct sunlight can speed up wear and make screen viewing more difficult

- Air Quality: Dust, smog, smoke, and other small particles may enter the device, potentially harming electronics or impeding airflow

- Humidity: Too much moisture can cause condensation, resulting in water damage or electrical shorts

- Shock and Vibration: Forces from nearby machinery can damage disk drives and loosen connections over time

As an example, consider a computer being used in an automatic car wash. For starters, the screen would likely be at least partially exposed to the outdoors, meaning the amount of sunlight, humidity, dust, and heat could change drastically from day to day. Water and soap from the main line might constantly splash onto the device and the surrounding area. A mouse and keyboard would probably not be appropriate, as the operators’ hands would often be wet. A computer would need to be specifically built to work in this environment, and this is exactly what IPCs are for.

Reliable Touchscreen Support

IPCs come in two main types: rack IPCs and panel IPCs. A rack IPC is built to fit on a traditional server rack, and typically does not include a monitor, keyboard, or mouse. A panel IPC, on the other hand, is an all-in-one device with a built-in touchscreen.

One advantage of a panel IPC is that the ratings apply not only to the processing components, but also to the display. This means workers can interact with SCADA programs and other software directly from the field, with no need for added peripherals. Compared to most consumer all-in-one PCs, panel IPC screens are more durable, have improved visibility, and maintain touch sensitivity longer.

Additionally, many panel IPCs can run HMI software from the same manufacturer. Because panel IPCs use touchscreens, the software can typically be run without modifying the user interface. This allows engineers to spend less time designing and more time testing, and can also lower licensing costs.

Communication Ports

Many automation systems use different kinds of serial devices. While it may be possible to indirectly connect these to an Ethernet network, it is much easier to connect directly to a computer running a SCADA program. For this reason, IPCs often have multiple RS-232C or RS-485 serial ports. A direct connection is much simpler, cheaper, and more reliable than relaying a signal across multiple protocols or cable types.

Additionally, most IPCs provide two Ethernet ports for improved Internet communication. In the event of a network failure, the IPC can utilize a backup connection on the second port. Separate ports can also be used to host dedicated services, as well as distribute the data load to avoid bottlenecking. In a SCADA system, this might mean the difference between an alarm signal being received or not received on time; network stability and predictability can be major safety concerns for industrial applications.

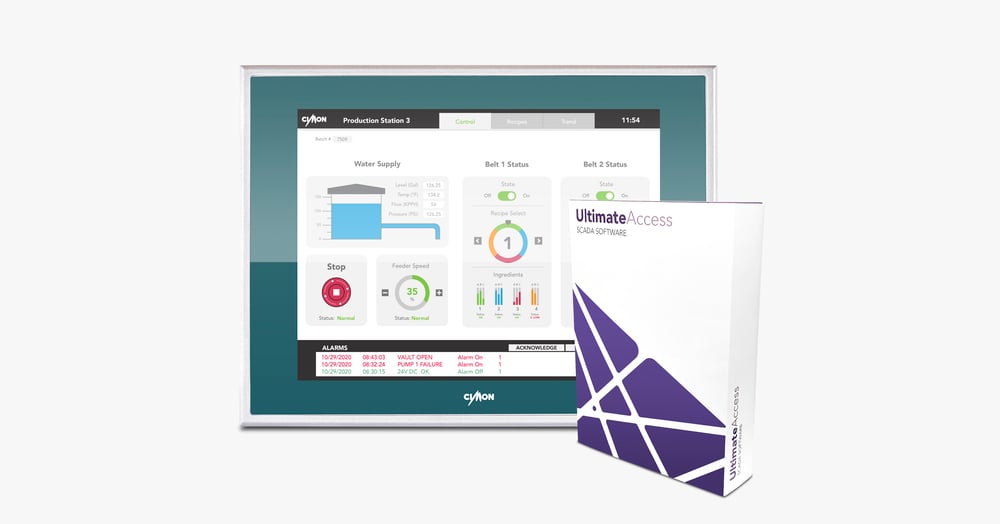

SCADA Bundle Support

Some manufacturers produce both IPCs and SCADA software, and it is generally cheaper to buy multiple products from the same company. For example, when you buy a CIMON IPC, you can also obtain any UltimateAccess SCADA licence at a discount. This results in a significantly lower cost than buying the products separately.

Another advantage of bundling your IPC is streamlined customer support and improved reliability. Because the SCADA software has already been tested on your specific hardware, it is easier to identify issues and receive assistance. With a third-party manufacturer, it can be difficult to determine whether issues are caused by hardware configuration, project settings, or other in-between factors.

CIMON IPC and UltimateAccess

If you are interested in using an IPC for your application, take a look at CIMON’s IPC product page. We offer rack and panel IPCs, UltimateAccess SCADA software, and also HMIs and PLCs for automation solutions of any size. With CIMON, customer support and design software are always freely available. You can also check out our library of training materials or sign up for online classes. Get started automating today!