What is HMI? A Closer Look at the Human Machine Interface and its Uses

As we explore the realm of industrial automation, the term Human-Machine Interface (HMI) often emerges. HMI refers to a user interface or dashboard that connects a person to a machine, system, or device, enabling interaction and control over various processes. In industrial settings, HMI is vital for operators to monitor and control processes, such as those in factories or power plants. HMI can take numerous forms, including graphical user interfaces (GUIs) on a computer, touchscreens, or physical control panels with buttons and displays. By making complex data more accessible and understandable, HMI allows for more efficient communication between humans and machines, ultimately optimizing the overall production process.

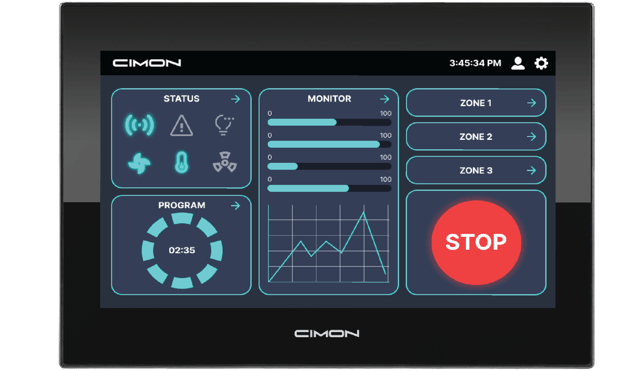

In this article, we will examine the intricacies of industrial HMI, its various applications, and the benefits it offers in the world of automation. We will also discuss how HMI and SCADA systems, like CIMON UltimateAccess SCADA and CIMON Xpanel HMI, are revolutionizing industrial processes and tasks. Join us as we delve into the fascinating world of industrial human-machine interfaces and uncover their potential in shaping the future of automation.

Industrial HMI and Its Significance

Industrial Human-Machine Interfaces (HMIs) play a crucial role in automation, enabling operators to control and monitor machinery in various settings. Well-designed HMIs adhere to ergonomic principles and engineering standards, ensuring user-friendly interaction. Hardware components, such as touchscreens and control panels, work with HMI software for visualization and data processing. Advanced HMI and SCADA software revolutionize industrial processes, enhancing data visualization, analytics, and user experience for increased efficiency and productivity.

HMIs complement Programmable Logic Controllers (PLCs) by providing an interface for human interaction with control systems, allowing operators to input commands and receive feedback. Essential in various industrial automation applications, HMIs enable operators to monitor and control processes in diverse industries like manufacturing, energy production, and chemical processing. Industrial HMIs optimize production processes and enhance efficiency in automation systems by bridging the gap between complex machinery and their human operators.

Versatile Applications of Industrial HMI Across Different Industries

Industrial HMI devices are crucial in various applications across multiple industries, enabling operators to interact with and control machines, systems, or devices for smooth and efficient operation. In manufacturing and factory automation, HMI systems control complex processes using SCADA software like CIMON UltimateAccess. They are also used for equipment and machinery monitoring, motion control, industrial automation, building automation, digital signage, and vending machines.

Additionally, HMI devices have applications in medical, automotive, and appliance sectors, facilitating seamless interaction between users and machines or systems. They play a vital role in automating complex production processes in fields such as oil and gas, electronics, steel production, textiles, electricity, and water. Industrial HMI devices' widespread use across multiple industries highlights their importance in today's automated and interconnected world.

The Benefits of Industrial HMI

The world of industrial automation has seen remarkable advancements in recent years, and one example is the area of software development. HMI software, such as CIMON Canvas and SCADA software like CIMON UltimateAccess, are sophisticated technology solutions that are revolutionizing industrial processes and tasks. With increasing demand for greater connectivity, efficiency, integrated functions, and cost-effectiveness in industrial automation, HMI software offers numerous benefits that can help optimize your system.

HMI plays a crucial role in connecting operators to machines and devices, allowing seamless interaction and data exchange. This connectivity enables faster decision-making and improved monitoring of industrial processes. HMI software provides user-friendly interfaces that allow operators to interact with machines and systems more effectively. With a more responsive HMI, operators can perform tasks with minimal effort, leading to increased productivity and cost-effectiveness.

HMI systems enable operators to track, monitor, and control various machines and systems from a single interface. This centralized approach streamlines operations, allowing a single worker to manage multiple screens and processes. Modern HMI displays provide operators with essential information about the processes they control. These advanced displays have evolved significantly and can present data in a more visually appealing and accessible format, enabling better decision-making. HMI software can be customized to accommodate a wide range of applications, from simple to complex systems. This adaptability ensures that HMI solutions can grow and evolve alongside changing industrial demands and advancements in technology. In conclusion, Industrial HMI offers numerous advantages that can significantly improve automation systems, paving the way for a more efficient and cost-effective future.

The Future of HMI

The future of HMI technology appears promising, with the integration of new innovation and advancements aimed at enhancing efficiency, user experience, and adaptability across various industrial applications. The evolution of HMI will involve a convergence of multiple technologies and disciplines, culminating in more powerful, intuitive, and user-friendly interfaces capable of effectively adapting to the rapidly changing industrial landscape.

As an increasing number of companies adopt high-performance HMI solutions, the emphasis shifts toward presenting the most critical information, allowing users to efficiently process data and avoid information overload. The adoption of multi-touch screens, remote monitoring, and cloud-based systems is also growing, further enhancing user interaction and providing greater accessibility to essential system information. This progress in HMI technology will contribute to improved efficiency and safety in various industries, paving the way for more sophisticated and adaptive human-machine interactions.

The Latest HMI from CIMON

CIMON's most recent HMI technology is showcased in the new XPANEL product line, featuring both the nXT and eXT series. The XPANEL nXT series is equipped with a capacitive touch screen and a UL Class 1 Div 2 certification, making it appropriate for use in hazardous environments. Meanwhile, the XPANEL eXT series offers a resistive touch screen and strikes an ideal balance between performance and affordability, making it an excellent option for those seeking a high-quality industrial HMI at a more budget-friendly price point. Regardless of whether the nXT or eXT series better suits your automation requirements, the CIMON XPANEL line of HMI displays are worth considering for your next project.

To program the HMI on the XPANEL devices, CIMON provides the Canvas software, which is bundled with the XPANEL HMIs. Canvas is a state-of-the-art HMI programming software with a modern and intuitive UI/UX that simplifies the process of creating, editing, and managing HMI projects, making it accessible to users of all skill levels. The powerful and versatile platform is a perfect solution for industrial automation.

Along with the impressive XPANEL product line, CIMON is also introducing the all-new UltimateAccess V4.0 SCADA software. This latest version includes a host of advanced features, such as 3D support, an HTML5 web server, IEC 61850 support, Historian, Page recorder, and features for FDA CFR 21 Part 11 compliance. These additions aim to enhance the overall user experience and ensure compliance with industry standards, making it an ideal solution for various industrial applications.

The world of industrial HMI is rapidly evolving, with industry-trusted technologies like CIMON UltimateAccess SCADA and CIMON Xpanel HMI driving this revolution. As the demand for more efficient, user-friendly, and adaptable systems continues to grow, we can expect HMI technology to play an increasingly important role in shaping the future of industrial automation. By providing a user-friendly interface for human-machine interaction, HMIs bridge the gap between complex machinery and the people who operate them, ultimately optimizing production processes and enhancing overall efficiency in automation systems.